Good arena footing is an investment. At Footing SolutionsUSA, we have been building private horse arenas and Showground competition arenas over the past 17 years. Building the perfect riding arena surface requires a lot of experience and a special understanding of the ideal riding surface, which can only be developed over time.

– Hilo Nick, founder Footing SolutionsUSA

For more than 15 years, synthetic arena footings have become popular in North America, following European countries who have used geotextile arena footing additives for decades.

While in the beginning only original geotextile blends consisting of needle felt and fibers specifically produced for horse arenas were used, like the GGT original blend from Germany, the US market has now become flooded with lower quality synthetic additives. We come across a lot of shredded, dusty, and contaminated carpet fibers, old bathroom rugs, mattresses, etc., sold as sand synthetic arena footing additives. These products are contaminated and also do not provide the ideal ratio of textile:fibers, resulting in overly compacted and hard arena footings or very loose and shifting arena surfaces.

Geotextile sand additives are mixed in with a quality sand. The sand quality is the most important part of the arena footing. A good sand should only be selected by a horse arena specialist. The ideal ratio of the geotextiles:fibers of synthetic sand additives depends on the sands available in certain areas of the country. Some sands will need more fibers than geotextiles or vice versa depending on the sand you start with.

We often come across arenas with too much fibers added, especially carpet fibers. In these scenarios, the mixture binds up together too much, resulting in the arena footing becoming overly compacted and too hard.

So when you decide to go with a synthetic arena footing, always consult with a quality arena footing company to approve the best sand selection and the appropriate geotextile blend to mix with it.

Geotextile Arena Footing

Geotextile Arena Footing Ground Mats and Grids

Ground Mats and Grids Subsurface Irrigation

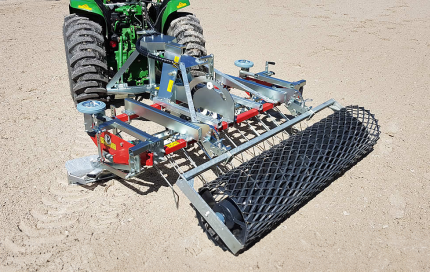

Subsurface Irrigation Arena Drags & Groomers

Arena Drags & Groomers Mirrors and Kickwall

Mirrors and Kickwall Horse Wellness

Horse Wellness Dust Control

Dust Control