The most common list of complaints when it comes to riding arenas are footing that is too hard; too deep; too uneven; too slippery; too dusty; and does not drain well. It is time to correct your wrongs and improve your arena footing.

What lies Beneath – The Arena Base

Arena problems usually start at the sub-base and the base. What is the arena sub-base? It is the correctly graded and compacted natural soil. Above the sub-base, the addition of the correct arena base material and depth of the base determine the future of the arena footing you are choosing for the top riding surface.

Arena problems usually start at the sub-base and the base. What is the arena sub-base? It is the correctly graded and compacted natural soil. Above the sub-base, the addition of the correct arena base material and depth of the base determine the future of the arena footing you are choosing for the top riding surface.

Putting brand new footing on the wrong arena base will create all sorts of long-term problems like base material mixing in with the arena sand, rocks from the base migrating into the footing, the list goes on.

If you have a natural clay base, then it is time to invest in building a proper arena base. Natural clay bases cause all kinds of problems. When it rains or the footing is over-watered, the clay loosens up and mixes with your beautiful sand you just invested in. The base also becomes super slick and will not drain well. The ideal solution is to seal off the clay base with a minimum 5 inch base of rock/stonedust or limestone aggregates, compacted to a 95% density. This will prevent the footing from mixing with the base.

How do I make my arena footing better?

First, determine if your riding arena needs repair. Check the depth and evenness of your footing through out the riding arena with a measuring stick. If you cannot probe down to the base, then you either have a lot of compacted old sand or the arena sand has mixed with the base material. If you find the base with your measuring stick and you have 2 inches on one side and 5 inches on the other side, then you need to get a laser grader out to re-laser and improve the arena footing. At this point, you need to ask yourself why the arena footing shifted around so much. The most common cause we see is that the watering is uneven, causing uneven dragging. Uneven watering is caused by overhead sprinklers which are fighting wind, evaporation and accuracy. If you have the budget, invest in one of our sub-surface irrigation systems. Ebb and flow arenas and the HIT Active Aqua arenas are gaining popularity for all climates.

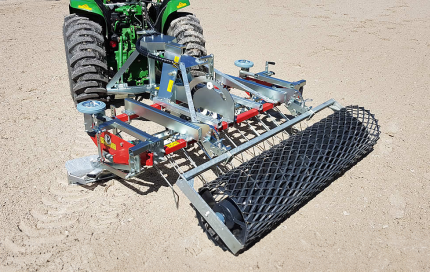

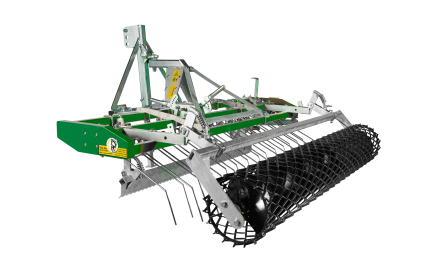

Another problem is the arena harrow itself. if the arena drag does not have a swivel attachment by the three-point hitch of your tractor, you will shift a lot of arena footing into the corners and circles, causing your arena footing to become uneven in a short period of time.

How do I assess arena footing?

How do I assess arena footing?

A simple test you can do yourself: Walk around your arena and stamp your toe into the arena surface. If you hit the base right away, then your footing is too loose and shifting around too much. This makes it hard for the horse to go into the “push-off” phase, putting strain on the ligaments and tendons.

To the contrary, if you cannot move any footing while pushing your toe into the surface and it hurts your own toe during stamping, then the arena surface is way too compacted. A horse should not be worked regularly on this type of arena footing. Pedal osteitis, navicular and bone remodeling are often the result and puts the future soundness of your horse at risk.

If your arena footing depresses slightly and stays under your foot, then you are in a green zone.

What is the lifespan of an arena surface?

The longevity of your arena depends on the type of sand and sand additives you are using. Sand with a high quartz percentage does not break down as fast as other types of sand. And, when mixed with geotextile additives, you can get up to 15 years out of your arena footing with good arena maintenance.

If you use concrete or washed plaster sand, then the lifespan of your arena footing will be much shorter, anywhere between 2-4 years.

When your footing’s lifespan comes to an end, it is better to replace the entire arena surface with new material rather than topping it off and bandaging it with a few loads of new sand, because this will have to be done more often, costing more in the long-run. Overall, it is more economical to invest your money in a good quartz sand and trucking cost, rather than buying local manufactured sands.

Geotextile sand additives are our choice of material to add cushion and stability to the sand arena. Learn why here.

Why Footing Solutions USA?

We are footing specialits, providing the high-quality products you need to keep your horse at peak performance. From sand additives and dust-free footing to arena maintenance and more, we’re here for you. To improve arena your footing, contact us today!

How do I assess arena footing?

How do I assess arena footing?

Geotextile Arena Footing

Geotextile Arena Footing Ground Mats and Grids

Ground Mats and Grids Subsurface Irrigation

Subsurface Irrigation Arena Drags & Groomers

Arena Drags & Groomers Mirrors and Kickwall

Mirrors and Kickwall Horse Wellness

Horse Wellness Dust Control

Dust Control