No matter what kind of footing you choose for your arena, it will not perform optimally without the appropriate base. For your footing to be successful, the riding arena base needs to be leveled and able to DRAIN properly. Easier said than done!

Arena Base Construction and Common Problem Areas

There’s a lot of information available about how to build the optimum arena base. But, just as important is knowing about potential sources of problems so you can fix them—before they happen. Following, we discuss the issues that frequently occur when building an arena from the base up.

1. Using only a clay base or an aggregate with a very high clay content

In locations like California (where Footing Solutions is HQed), there is an abundance of clay soil—which is extremely hard for nine months of the year, making it very tempting and it is very intriguing to use as your long-term arena base.

Problem: But once rainy season strikes, all bets are off. Arena bases that are made only with this natural clay end up breaking up, leaving clay to migrate into your nice arena footing on top. This not only contaminates the arena surface and leaves you with a muddy mess, but slick horse arena footing can lead to all types of injuries in horses.

Suggestion: Never build your outdoor horse arena just on a clay base. Always follow the instructions of a professional arena builder when constructing the arena base.

2. Free Draining Base with landscape fabric

A free draining base is commonly used in high-precipitation climates. The free draining base consists of a thick layer of gravel or DrainRock covered with a landscape fabric as a separation layer between the gravel and your precious arena footing. Then the arena footing is placed on top of the fabric.

Problem: While the free draining base guarantees excellent vertical drainage, critters like moles, gophers, natural erosion and other factors can shift the gravel and the landscape fabric. The fabric starts moving and eventually makes its way up into your arena footing, causing dangerous traps for your horse’s legs!

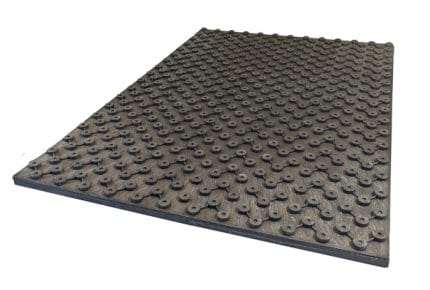

Solution: A proper separation layer. At Footing Solutions USA, we never build a free draining arena base without using a safe, permanent separation layer with base grids or mats.

3. Common Arena Base with horizontal surface drainage

After it precipitates, a common arena base built properly with the right aggregates and slope—with arena footing consisting of a clean, washed sand and geotextile additives—will dry up in 1-3 days.

Problem: Oftentimes it takes longer for this type of base to dry. When faced with this issue, it means the arena base is either not sloped well enough, is not sloped evenly, or, it simply has the wrong base material aggregate with too much clay and silt fines in it.

Solution: Consult a professional to ensure your arena is built correctly the first time and provide an optimal riding surface.

Geotextile Arena Footing

Geotextile Arena Footing Ground Mats and Grids

Ground Mats and Grids Subsurface Irrigation

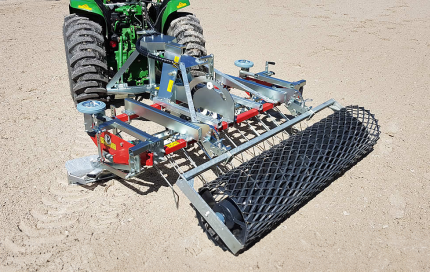

Subsurface Irrigation Arena Drags & Groomers

Arena Drags & Groomers Mirrors and Kickwall

Mirrors and Kickwall Horse Wellness

Horse Wellness Dust Control

Dust Control